Welcome to the LiftMaster LA400 manual, your comprehensive guide to installing, operating, and maintaining the LA400 medium-duty swing gate operator. Designed for vehicular gates, this manual ensures safe and efficient operation, complying with UL 325 standards and featuring advanced safety mechanisms like entrapment protection. Proper installation by a trained technician is essential for optimal performance and security.

1.1 Overview of the LA400 Gate Operator

The LiftMaster LA400 is a medium-duty swing gate operator designed for vehicular gates, suitable for Class I, II, and III applications. It features a robust design, UL 325 compliance, and advanced safety mechanisms like entrapment protection. Available in models such as LA400PKGUL, LA400DC, and LA400DCS, it offers compatibility with various accessories, including remote controls, ensuring reliable and secure gate operation for residential and light commercial use.

1.2 Purpose and Scope of the Manual

This manual provides detailed instructions for the installation, operation, and maintenance of the LiftMaster LA400 gate operator. It serves as a reference for understanding safety guidelines, technical specifications, and troubleshooting procedures. The scope includes compliance with UL 325 standards, ensuring reliable and secure operation. Intended for both users and technicians, it covers essential steps to maximize performance and longevity of the LA400 system.

Key Features of the LiftMaster LA400

The LiftMaster LA400 offers UL 325 compliance, advanced safety mechanisms, and energy-efficient operation. It supports single or dual swing gates, ensuring reliable performance for vehicular access control.

2.1 Design and Compatibility

The LiftMaster LA400 is designed for vehicular swing gates, supporting Class I, II, and III applications. It is compatible with single or dual gate setups, offering a robust and flexible solution. The operator is UL 325 compliant, ensuring safety and reliability. Its compact design and durable construction make it suitable for residential and light commercial use, providing efficient gate operation in various settings.

2.2 Safety and Compliance Standards

The LiftMaster LA400 adheres to UL 325 standards, ensuring safety and compliance for residential and light commercial gate applications. It features entrapment protection sensors and non-contact safety devices to prevent accidents. The operator is designed with secure locking mechanisms and emergency release functions, meeting industry regulations for reliability and user protection. Compliance with these standards guarantees a safe and reliable gate operating system.

System Components and Hardware

The LA400 system includes a control box, linear actuator arms, mounting hardware, and accessories like junction boxes and terminal blocks for reliable gate operation.

3.1 Control Box and Accessories

The LA400 control box is the central hub, housing essential components for operation. It includes a hardware bag with mounting screws, anchors, and a terminal block. Accessories like the six-conductor extension cable and junction box ensure seamless connectivity. The control box also supports optional features like solar power and wireless communication, enhancing functionality and convenience.

3.2 Actuator Arms and Mounting Hardware

The LA400 features durable actuator arms, available in 1K and 2K models, designed for reliable performance. Mounting hardware includes robust components ensuring secure installation. Proper alignment and torque settings are crucial for optimal functionality. The arms are constructed to withstand various environmental conditions, ensuring long-lasting operation and minimal maintenance for vehicular swing gates.

Installation Instructions

Installation of the LiftMaster LA400 requires a trained technician to ensure safety and compliance with UL 325 standards. Follow manual instructions for proper setup, wiring, and testing.

4.1 Pre-Installation Checklist

Before installing the LiftMaster LA400, ensure the site is prepared and all components are available. Verify compatibility with gate type and size, ensuring proper alignment and clearance. Check for UL 325 compliance and install entrapment protection sensors as required. Review safety guidelines, inspect hardware for damage, and confirm power sources meet specifications. Ensure control box and actuator arms are included and compatible with your gate system.

4.2 Step-by-Step Installation Process

Mount the control box securely and connect the actuator arms to the gate. Install entrapment sensors and ensure proper alignment. Wire the system according to the diagram, connecting solenoid locks and sensors. Test the gate’s manual release and ensure smooth operation. Follow safety guidelines and verify all connections before powering up. Perform a final test to ensure proper functionality and compliance with safety standards.

Safety Guidelines and Precautions

Always read the manual fully before installation or operation. Ensure UL 325 compliance and proper entrapment protection. Only trained technicians should install or service the system. Exercise caution during gate movement to prevent accidents and follow all safety warnings provided.

5.1 General Safety Information

The LiftMaster LA400 gate operator is designed for safe operation, but proper precautions are essential. Always follow UL 325 standards and ensure entrapment protection devices are correctly installed. This system is intended for vehicular gates only, and improper use can lead to serious injury. Keep gates away from pedestrian pathways and ensure clear visibility during operation. Regular maintenance is crucial to prevent unexpected malfunctions.

Never attempt adjustments or repairs without proper training. Only authorized personnel should service the system. Always monitor gate movement and keep children away during operation. Failure to adhere to these guidelines may result in injury or damage. Refer to the manual for detailed safety protocols and compliance requirements.

5.2 Entrapment Protection and Sensors

Entrapment protection is critical for safe operation. The LA400 requires non-contact sensors to detect obstructions, ensuring the gate stops or reverses upon contact. Proper sensor placement is essential to prevent accidents. Refer to the manual for specific installation guidelines and ensure compliance with UL 325 standards. Regularly test sensors to confirm functionality and adjust as needed to maintain reliable operation and safety.

Wiring and Electrical Connections

Refer to the wire diagram for correct connections. Solenoid locks use NO and C terminals, while maglock connections are accurate. Ensure all wiring meets safety standards.

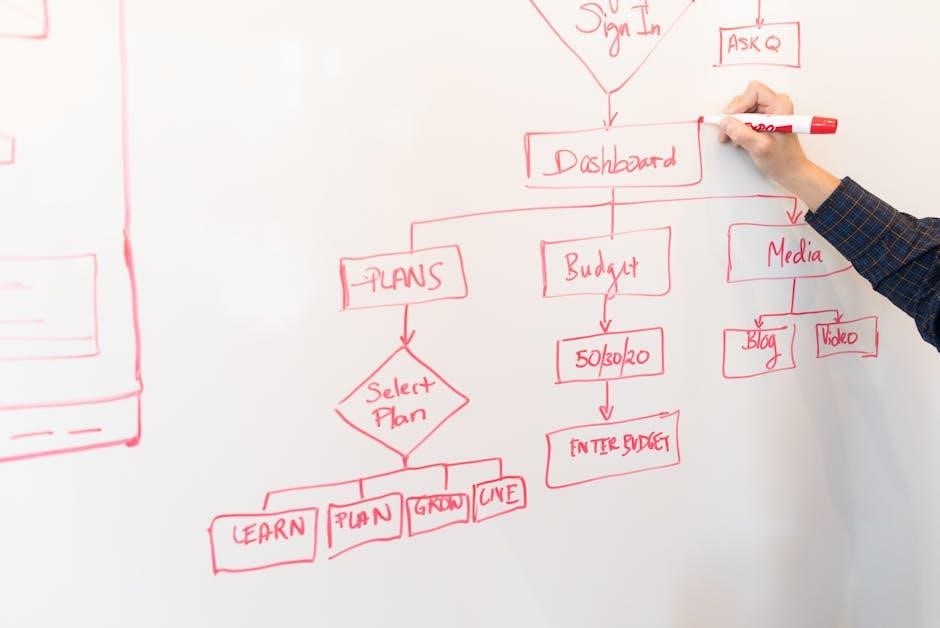

6.1 Wire Diagram and Connections

The wire diagram provides a detailed guide for connecting components. Note that solenoid lock connections were initially incorrect but have been corrected to use NO and C terminals instead of NC. Maglock connections, however, are accurate as shown. Ensure all wires are securely connected to avoid malfunction. Always follow safety standards and manufacturer guidelines to prevent electrical hazards or system damage. Proper wiring is crucial for reliable operation.

6.2 Solenoid Lock and Maglock Wiring

For the solenoid lock, use the NO (normally open) and C (common) terminals on the control board. The maglock connections are correct as indicated in the wiring diagram. Ensure all connections are secure to prevent malfunctions. Follow the manual’s guidelines for proper wiring to maintain safety and functionality. Always double-check connections before powering up the system.

Operation and Maintenance

Regularly monitor the gate’s performance and ensure all safety features function correctly. Perform routine maintenance, such as lubricating moving parts and checking electrical connections, to maintain optimal operation.

7.1 Daily Operation and Monitoring

Daily operation involves ensuring smooth gate movement and verifying all safety devices function correctly. Monitor the gate’s cycles, checking for unusual noises or irregular motion. Regularly inspect the actuator arms and sensors to ensure proper alignment and responsiveness. Keep the control box clean and free from obstructions. Log any issues or malfunctions for prompt maintenance to maintain reliability and safety.

7.2 Regular Maintenance and Upkeep

Regular maintenance is crucial for optimal performance. Lubricate moving parts every six months and check electrical connections for wear or corrosion. Inspect and replace worn components like hinges and rollers. Clean dirt or debris from sensors and photo eyes to ensure accurate operation. Schedule annual professional inspections to address potential issues before they escalate, ensuring longevity and reliability of the LA400 gate operator.

Troubleshooting Common Issues

Identify and resolve common issues like gate reversing unexpectedly or sensors malfunctioning. Check error codes, ensure proper sensor alignment, and verify wiring connections for optimal functionality.

8.1 Identifying and Diagnosing Problems

Start by checking error codes on the control panel for specific issue indicators. Verify sensor alignment and wiring connections, ensuring no obstructions block sensor paths. Consult the manual for detailed diagnostic steps and troubleshooting charts. If issues persist, contact an authorized technician for professional assistance to resolve complex malfunctions effectively.

8.2 Solutions for Common Malfunctions

Refer to the manual for specific solutions. Address wiring issues by correcting solenoid lock connections using NO and C terminals. Ensure sensors are aligned and free of obstructions. Restart the system after resolving issues. For persistent problems, consult the troubleshooting guide or contact a certified technician. Regular maintenance and proper alignment can prevent recurring malfunctions, ensuring smooth gate operation and safety.

Accessories and Compatible Products

The LiftMaster LA400 supports various accessories, including remote controls, keychain options, and solar-powered solutions. These enhance functionality and convenience, ensuring compatibility with your gate system.

9.1 Remote Controls and Keychain Options

LiftMaster offers a range of remote controls and keychain options for the LA400, ensuring convenient gate operation. Choose from single-button to four-button remotes, designed for visor or keychain use. These remotes are compatible with the LA400’s 315 MHz frequency, providing reliable control. Keychain remotes are ideal for effortless access, while multi-button options allow operation of multiple gates or additional accessories. Programming is straightforward, and the remotes feature rolling code technology for enhanced security.

- Single-button to four-button remote options

- Keychain remotes for added convenience

- Compatible with 315 MHz frequency

- Easy programming and secure rolling code technology

9.2 Solar-Powered and Wireless Solutions

The LiftMaster LA400 supports solar-powered and wireless solutions, offering eco-friendly and cost-effective options. Solar-powered systems reduce energy costs and environmental impact, while wireless communication eliminates the need for driveway trenching. These solutions enhance convenience and efficiency, ensuring seamless gate operation without compromising performance. Key features include energy efficiency and dual-gate synchronization capabilities.

- Solar-powered systems for reduced energy costs

- Wireless communication to eliminate trenching

- Dual-gate synchronization

- Energy-efficient design

Compliance and Certification

The LiftMaster LA400 complies with UL 325 standards and is UL 991 certified, ensuring safety and reliability. It meets industry regulations for residential gate operators, providing peace of mind through rigorous testing and certification processes.

10.1 UL 325 Standards Compliance

The LiftMaster LA400 adheres to UL 325 standards for residential and commercial gate operators, ensuring safety through features like automatic entrapment protection and proper sensing devices. Compliance is verified through rigorous testing, covering aspects such as force limits, obstacle detection, and operational reliability. This certification guarantees the operator meets industry safety requirements, reducing risks and ensuring durability in various applications.

10.2 Industry Certifications and Ratings

Beyond UL 325, the LiftMaster LA400 holds additional certifications, underscoring its commitment to quality and safety. It meets stringent industry ratings for performance, energy efficiency, and environmental sustainability. These recognitions ensure the operator is reliable, eco-friendly, and suitable for diverse installations, aligning with global standards for gate automation and security systems. Such certifications enhance user trust and product reliability.

Environmental and Energy Efficiency

The LiftMaster LA400 features energy-efficient DC motor technology and eco-friendly design elements, reducing environmental impact while ensuring reliable performance for vehicular swing gate applications.

11.1 Energy-Saving Features

The LiftMaster LA400 incorporates a 24V DC motor, optimizing energy efficiency while maintaining powerful performance. Its low-power consumption design reduces operational costs. The system includes a plug-in transformer and battery backup, ensuring energy efficiency and reliability during power outages. Solar-powered solutions are also available, enhancing eco-friendliness and reducing dependence on traditional energy sources. These features make the LA400 an environmentally responsible choice for gate automation.

11.2 Eco-Friendly Design Elements

The LiftMaster LA400 is designed with eco-conscious engineering, featuring recyclable materials in its control box and hardware. Its energy-efficient 24V DC motor minimizes power consumption and reduces carbon footprint. Solar-powered solutions are available, offering a sustainable alternative for operation. These eco-friendly design elements reflect LiftMaster’s commitment to environmental sustainability while delivering reliable performance and durability for gate automation needs.

Customer Support and Resources

LiftMaster offers comprehensive support through their website, including downloadable manuals, troubleshooting guides, and a dealer locator; Visit www.liftmaster.com for assistance or to find authorized technicians near you.

12.1 Accessing the Full Manual Online

To access the full LiftMaster LA400 manual, visit the official LiftMaster website at www.liftmaster.com. This comprehensive guide includes safety warnings, specifications, wiring diagrams, and detailed instructions for installation, operation, and maintenance. Reading the manual thoroughly before starting any work ensures compliance with safety standards and proper functionality of your gate operator.

12.2 Finding Authorized Dealers and Technicians

To locate authorized dealers and technicians for the LiftMaster LA400, visit the official LiftMaster website at www.liftmaster.com. This resource provides a dealer locator tool to find certified professionals in your area. Authorized technicians ensure proper installation, maintenance, and compliance with UL 325 standards. They also offer expertise in troubleshooting and upgrading your gate operator system for optimal performance and safety.

The LiftMaster LA400 manual provides essential guidance for safe and effective gate operation. Proper installation, regular maintenance, and adherence to safety protocols ensure reliability and longevity. Always refer to authorized dealers for professional assistance, and follow UL 325 standards for optimal performance and security.

13.1 Summary of Key Points

The LiftMaster LA400 manual outlines essential steps for installing, operating, and maintaining the medium-duty swing gate operator. Designed for vehicular gates, it emphasizes safety, UL 325 compliance, and proper installation by trained technicians. Key features include entrapment protection, energy efficiency, and compatibility with accessories like remote controls and solar-powered solutions. Adhering to the manual ensures reliable performance, security, and longevity of the gate operator system.

13.2 Importance of Proper Installation and Maintenance

Proper installation and maintenance are critical for ensuring the LiftMaster LA400 operates safely and efficiently. Incorrect installation can lead to mechanical failures and safety hazards, while neglecting maintenance may result in reduced performance and lifespan. Regular inspections, lubrication of moving parts, and adherence to the manual’s guidelines are essential to uphold functionality, security, and compliance with safety standards, ensuring long-term reliability and optimal gate operation.