Fundamentals of Instruction Test: A Comprehensive Plan

Fundamentals of instruction testing involve utilizing tools like TestRail to enhance efficiency and reliability. King Schools’ FOI prep focuses on conveying information effectively, while automation streamlines testing procedures.

Instruction testing is a systematic process crucial for evaluating the effectiveness of teaching and learning materials. It goes beyond simply assessing knowledge recall; it delves into how well individuals comprehend and can apply learned concepts. This field leverages various methods, including utilizing platforms like Lagged.com for engaging practice and TestRail for structured testing management.

The core aim is to ensure instructional content achieves its intended learning objectives. This involves designing tests that accurately measure understanding, utilizing diverse question types – from multiple-choice to essay questions – to gauge different cognitive levels. Resources like King Schools FOI prep emphasize a focus on fundamental principles, preparing candidates for rigorous evaluation.

Modern approaches increasingly incorporate test automation, enhancing efficiency and reliability. Understanding these fundamentals is the first step in creating impactful and effective instruction.

The Core Principles of Effective Instruction

Effective instruction, and consequently, effective instruction testing, hinges on several core principles. Clarity of learning objectives is paramount; tests must directly assess these stated goals. Utilizing a variety of question formats – mirroring approaches found in King Schools FOI prep – caters to diverse learning styles and assesses comprehension at multiple levels.

Engagement is also key. Incorporating interactive elements, similar to the games available on platforms like Lagged.com, can enhance motivation and improve retention. Furthermore, consistent feedback is vital, allowing learners to identify areas for improvement.

Robust testing procedures, often managed through tools like TestRail, ensure fairness and reliability. These principles, when combined, create a learning environment where assessment isn’t merely evaluation, but a catalyst for growth and deeper understanding of the fundamentals.

Understanding Learning Objectives

Clearly defined learning objectives are the cornerstone of effective instruction and, crucially, of sound instruction testing; These objectives dictate what knowledge and skills learners should possess after completing a module or course. A well-crafted objective is specific, measurable, achievable, relevant, and time-bound (SMART).

When designing instruction tests, each question must directly align with a stated learning objective. This ensures content validity – that the test accurately reflects what was taught. For example, King Schools FOI prep materials focus on conveying fundamentals, so tests should assess understanding of those core concepts.

Without clear objectives, testing becomes arbitrary and fails to provide meaningful feedback; Utilizing tools like TestRail can help track objective coverage and ensure comprehensive assessment. Ultimately, understanding learning objectives is paramount for creating valid and reliable instruction tests.

Bloom’s Taxonomy and Instruction Test Design

Bloom’s Taxonomy provides a hierarchical framework for categorizing educational learning objectives, significantly impacting instruction test design. It ranges from lower-order thinking skills – remembering and understanding – to higher-order skills like applying, analyzing, evaluating, and creating.

Effective instruction testing shouldn’t solely focus on recall. A comprehensive assessment incorporates questions that evaluate all levels of Bloom’s Taxonomy. For instance, multiple-choice questions can assess understanding, while essay questions can evaluate critical thinking and application of fundamentals.

Considering this taxonomy ensures tests aren’t just measuring memorization but also a learner’s ability to utilize knowledge. Tools like TestRail can facilitate the organization of questions based on these cognitive levels. Aligning tests with Bloom’s Taxonomy enhances validity and provides a more holistic evaluation of learning, mirroring the goals of programs like King Schools’ FOI prep.

Types of Instruction Tests

Various instruction test types cater to different assessment needs. Multiple-choice questions efficiently assess broad knowledge, while true/false questions quickly gauge understanding of core fundamentals. Short answer questions demand concise comprehension, bridging recall and application.

Essay questions, however, excel at evaluating critical thinking and analytical skills, demanding more elaborate responses. The selection of test types should align with learning objectives and the desired depth of assessment. A balanced approach, incorporating diverse question formats, provides a more comprehensive evaluation.

Furthermore, utilizing platforms like TestRail allows for streamlined management of these varied question types. King Schools’ FOI test prep likely employs a mix of these formats to ensure a thorough understanding of the material. Effective testing isn’t about a single method, but strategic implementation of multiple approaches.

Multiple-Choice Questions: Best Practices

Crafting effective multiple-choice questions is crucial for accurate assessment; Distractors – incorrect answer options – should be plausible yet demonstrably wrong, avoiding overly obvious choices. Each question should focus on a single, clear learning objective, aligning with the fundamentals of instruction.

Avoid using “all of the above” or “none of the above” excessively, as they can sometimes encourage guessing. Ensure the stem (the question itself) is concise and clearly worded, leaving no room for ambiguity.

Regular item analysis, facilitated by tools like TestRail, helps identify problematic questions needing revision. King Schools’ FOI test prep likely emphasizes well-constructed multiple-choice questions to efficiently evaluate foundational knowledge. Remember, the goal is to measure understanding, not trick students.

True/False Questions: Avoiding Ambiguity

True/False questions, while seemingly simple, are prone to ambiguity. Absolute terms like “always” or “never” often signal a false statement, giving clues to test-takers. Focus on assessing core fundamentals of instruction, but avoid overly specific or nuanced details best suited for other question types.

Statements should be concise and clear, avoiding double negatives or complex sentence structures. Ensure the statement is unequivocally true or false, leaving no room for interpretation.

A high proportion of true statements can lead to guessing, while too many false statements can frustrate students. Careful review and item analysis, potentially using tools like TestRail, are vital. King Schools’ FOI test preparation likely minimizes reliance on True/False due to inherent limitations in accurately gauging comprehension.

Short Answer Questions: Assessing Comprehension

Short answer questions effectively assess a student’s understanding of the fundamentals of instruction beyond simple recall. They require concise explanations, demonstrating comprehension rather than just recognition of facts. These questions bridge the gap between multiple-choice and essay formats, offering a balanced assessment.

When crafting these questions, focus on key concepts and principles. Avoid ambiguity by clearly defining the expected scope of the answer. A well-designed question prompts students to articulate their understanding in their own words, revealing gaps in knowledge.

Grading requires a rubric to ensure consistency and fairness. Consider utilizing a scoring guide that outlines specific criteria for evaluating responses. TestRail, or similar testing platforms, can aid in organizing and scoring these types of questions, streamlining the evaluation process, similar to King Schools’ FOI approach.

Essay Questions: Evaluating Critical Thinking

Essay questions are crucial for evaluating a student’s ability to apply the fundamentals of instruction and demonstrate critical thinking skills. Unlike short answers, essays demand a more in-depth exploration of a topic, requiring students to synthesize information and formulate well-supported arguments.

Effective essay prompts should be open-ended, encouraging diverse perspectives and analytical reasoning. They should align directly with learning objectives, assessing a student’s capacity to analyze, evaluate, and create. Clear instructions regarding length and scope are essential to manage expectations.

Grading essays necessitates a detailed rubric focusing on content, organization, clarity, and argumentation. Utilizing testing tools like TestRail can assist in rubric management and consistent scoring. Similar to the FOI prep, the goal is to assess not just what students know, but how they apply that knowledge.

Test Validity and Reliability

Test validity and reliability are paramount when assessing the fundamentals of instruction. Validity ensures the test measures what it intends to measure – accurately reflecting learning objectives. Reliability refers to the consistency of the test; a reliable test yields similar results under consistent conditions.

Without validity, a test is meaningless, regardless of its reliability; A reliable but invalid test consistently measures the wrong thing. Both are crucial for making informed decisions about student learning and instructional effectiveness.

Employing robust testing procedures, like those supported by tools such as TestRail, aids in establishing both. Analyzing item difficulty and discrimination indices, as part of test analysis, contributes to improving validity. King Schools’ FOI course emphasizes a solid foundation, and the assessment must reflect that.

Ensuring Content Validity in Instruction Tests

Content validity, a cornerstone of effective instruction testing, confirms that the assessment comprehensively covers all relevant material taught. This means the test questions align directly with the learning objectives and the scope of the course content, like those emphasized in King Schools’ FOI prep.

Achieving content validity requires a systematic approach. Subject matter experts should review the test questions to ensure accuracy and representation of key concepts. A blueprint outlining the proportion of questions from each topic is beneficial.

Regular item analysis, identifying problematic questions, is crucial. Questions consistently missed may indicate gaps in instruction or issues with the question itself. Utilizing tools like TestRail can aid in organizing and analyzing test data, supporting the process of maintaining strong content validity and improving instructional strategies.

Measuring Test Reliability: Methods and Importance

Test reliability, a critical aspect of instruction testing, refers to the consistency of test results. A reliable test yields similar scores when administered repeatedly to the same individuals, assuming no learning occurs between administrations. This consistency is vital for making accurate inferences about student learning, particularly when utilizing resources like King Schools’ FOI materials.

Several methods exist to measure reliability. The test-retest method involves administering the same test twice to the same group. Internal consistency assesses how well items within a test measure the same construct. Utilizing item analysis, including difficulty and discrimination indices, contributes to this assessment.

Employing test automation tools, such as TestRail, can streamline data collection and analysis, facilitating reliable measurement. High reliability ensures the test accurately reflects student knowledge and informs instructional improvements.

Standardization in Instruction Testing Procedures

Standardization in instruction testing is paramount for ensuring fair and accurate evaluations. It involves establishing uniform procedures for test administration, scoring, and interpretation. Consistent protocols minimize extraneous variables that could influence results, allowing for valid comparisons between students and across administrations. This is especially crucial when preparing with resources like King Schools’ FOI materials, where consistent application of knowledge is key.

Standardized procedures encompass factors like time limits, instructions, and environmental conditions. Utilizing test automation tools, such as TestRail, can enforce standardization by automating test delivery and data collection.

Adhering to standardized protocols enhances the reliability and validity of test scores, providing a more equitable assessment of student learning. Proper standardization ensures that the test measures what it intends to measure, free from bias or inconsistencies.

Test Analysis and Interpretation

Test analysis and interpretation are critical steps following instruction testing, transforming raw data into meaningful insights. This process involves examining item performance – identifying problematic questions through item analysis – and calculating statistics like difficulty and discrimination indices. Understanding these metrics reveals whether questions effectively differentiate between high- and low-performing students.

Analyzing test results allows instructors to pinpoint areas where students struggled, indicating potential weaknesses in instruction. This data-driven approach, facilitated by tools like TestRail, informs instructional adjustments and curriculum refinement.

Interpretation extends beyond simply identifying incorrect answers; it requires considering the broader context of learning objectives and Bloom’s Taxonomy. Effective interpretation guides targeted interventions and ensures future instruction addresses identified gaps, ultimately improving student outcomes and reinforcing the fundamentals.

Item Analysis: Identifying Problematic Questions

Item analysis is a cornerstone of effective instruction testing, focusing on evaluating individual question performance. This process helps pinpoint problematic questions that may not accurately assess student understanding or contribute to reliable test scores. Analyzing student responses reveals patterns – consistently missed questions, or those with little discrimination between high and low achievers – signaling potential issues.

Problematic questions might be ambiguous, poorly worded, or misaligned with learning objectives. Identifying these flaws is crucial for improving test validity and ensuring fair assessment. Tools and techniques, like calculating difficulty and discrimination indices, provide quantitative data to support these evaluations;

By systematically reviewing each item, instructors can refine their assessments, strengthening the connection between testing and the fundamentals of instruction, ultimately leading to more accurate and meaningful evaluations of student learning.

Difficulty Index and Discrimination Index Explained

The difficulty index, a key metric in instruction testing, reveals the proportion of students who correctly answer a specific question. A high index suggests an easy question, while a low index indicates a challenging one. This informs instructors about the test’s overall accessibility and helps balance question difficulty.

Complementing this is the discrimination index, which assesses a question’s ability to differentiate between high-achieving and low-achieving students. A positive index signifies that stronger students are more likely to answer correctly, indicating a well-designed question aligned with course fundamentals.

Conversely, a negative or low discrimination index suggests a flawed question – potentially ambiguous or favoring students with weaker understanding. Analyzing both indices provides valuable insights for refining assessments and ensuring they accurately measure student comprehension.

Using Test Results to Improve Instruction

Analyzing instruction test results is crucial for iterative improvement of teaching methods. Item analysis, focusing on difficulty and discrimination indices, pinpoints problematic questions needing revision or removal. Identifying consistently missed concepts reveals areas where instruction requires reinforcement, ensuring a stronger grasp of fundamentals.

Furthermore, understanding student performance patterns – common errors or misconceptions – allows instructors to tailor future lessons. This data-driven approach moves beyond subjective assessment, providing concrete evidence for pedagogical adjustments.

Leveraging testing platforms like TestRail facilitates efficient data collection and analysis, streamlining the process of identifying areas for improvement. Ultimately, utilizing test results transforms assessment from a mere evaluation tool into a powerful catalyst for enhanced instruction.

Test Automation Fundamentals

Test automation is becoming essential in modern instructional design, mirroring its importance in software development. It significantly boosts testing efficiency, allowing for more frequent and reliable evaluations of learning materials. While traditionally manual, assessing comprehension through automated systems offers scalability and consistency.

Applying automation to instruction tests involves utilizing platforms like TestRail to manage and execute assessments. This reduces the burden of repetitive tasks, freeing up instructors to focus on analyzing results and refining content. Automated systems can also provide immediate feedback to learners, enhancing the learning experience.

Understanding the fundamentals of automation – scripting, execution, and reporting – is key to successfully integrating it into the instructional process, ultimately improving the quality and effectiveness of learning programs.

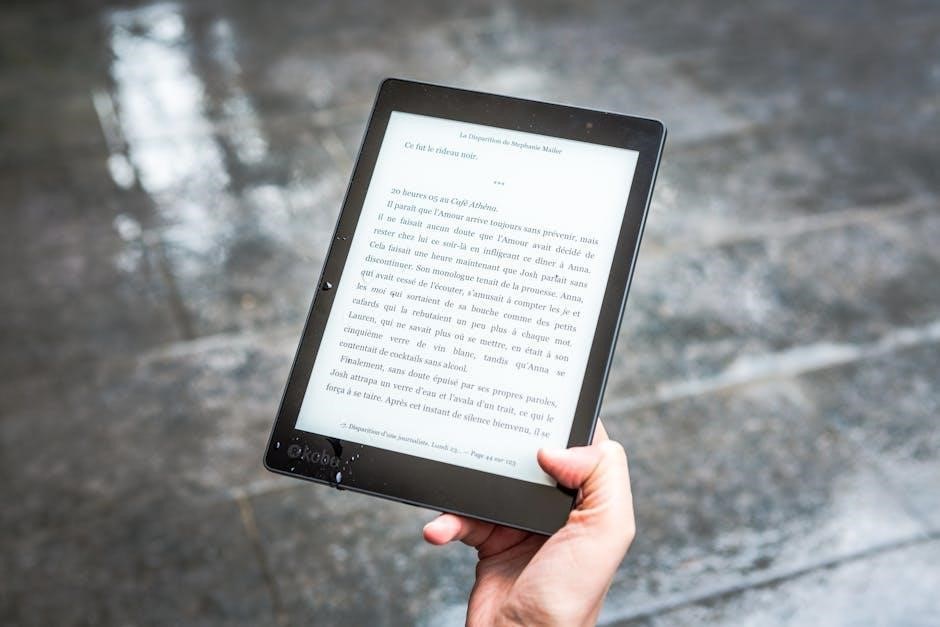

TestRail emerges as a powerful tool for managing and executing instruction tests, streamlining the evaluation process. Designed for both manual and automated testing, it provides a centralized platform for organizing test cases, tracking results, and generating reports. This is particularly valuable when assessing the fundamentals of instruction, ensuring learning objectives are met.

For instructors, TestRail facilitates the creation of comprehensive test plans aligned with course content. Its features allow for detailed test case descriptions, expected results, and actual outcomes, fostering a clear understanding of learner performance. The platform’s reporting capabilities offer valuable insights into areas needing improvement.

As a tool intended for new users, mastering TestRail’s core functionalities – project creation, test case management, and result analysis – is crucial for effective instruction evaluation.

King Schools FOI Test Prep: A Focus on Fundamentals

King Schools’ Fundamentals of Instruction (FOI) Interactive Video Ground School and Test Prep Course prioritizes effective knowledge conveyance. The course isn’t about memorization, but understanding core instructional principles. The accompanying test prep isn’t designed to simply present questions; it’s a study guide reinforcing these fundamentals.

The full FOI test comprises 50 questions, designed to assess comprehension of instructional methodologies. These questions aren’t necessarily identical to actual exam questions, but serve as a valuable self-assessment tool. Preparation emphasizes grasping the underlying concepts, ensuring instructors can effectively teach and evaluate learning.

Success in the FOI test demonstrates a solid foundation in instructional design, crucial for delivering impactful and engaging learning experiences. It’s a key step in the Instructor Development Pathway.

Resources and Further Learning

For those seeking to deepen their understanding of instruction testing, numerous online platforms offer valuable resources. Lagged.com and Crazy Games provide a diverse range of games, indirectly fostering problem-solving skills applicable to test design. Friv offers a long-standing collection of online games, promoting engagement with interactive learning.

Specifically regarding testing tools, exploring TestRail’s documentation and tutorials is highly recommended. Understanding test automation fundamentals is crucial in modern software development, enhancing efficiency and reliability. Several websites offer free online games for various interests, from action to puzzles, providing a break while reinforcing cognitive abilities.

Continued learning and practical application are key to mastering instruction testing. Regularly reviewing instructional design principles and utilizing available resources will contribute to ongoing professional development.