Heatilator Gas Fireplace User Manual: A Comprehensive Guide

This manual provides essential safety, installation, operation, and maintenance guidance for your Heatilator gas fireplace, ensuring reliable and efficient performance․

Understanding Your Heatilator Fireplace

Your Heatilator gas fireplace is engineered for safety, reliability, and efficiency, offering a beautiful and convenient heating solution․ This guide details crucial aspects of your unit, from identifying the model and locating essential information like the rating plate, to understanding proper installation and operational procedures․

Familiarize yourself with the specific features of your model – whether it’s a Crave series (36, 60, 72, or Linear 6048) or a CD series (4842IR-D, 4236IR-D)․ Proper understanding ensures optimal performance and longevity, allowing you to enjoy the warmth and ambiance for years to come․

Model Identification and Serial Numbers

Locating your Heatilator fireplace’s model and serial numbers is crucial for accurate service, parts ordering, and warranty claims․ These identifying numbers are found on the rating plate, a metal plate permanently affixed to your fireplace, insert, or stove․

The rating plate contains vital information about your specific unit, including the model number (e․g․, Crave 36 Rev C 36, CD4842IR-D) and the serial number․ Record these numbers in a safe place for future reference․ Having this information readily available will streamline any interactions with Heatilator customer support or authorized dealers․

Locating the Rating Plate

The rating plate, a metallic label containing essential information, is permanently attached to your Heatilator fireplace․ Its precise location varies by model, but it’s typically found on the fireplace’s chassis, near the gas connection, or within the firebox itself․

Carefully inspect the sides, back, and bottom of the unit․ The plate displays the model number, serial number, and other critical specifications․ Refer to your specific model’s installation manual for a detailed diagram pinpointing the rating plate’s exact location․ Knowing where to find this plate is vital for service and warranty purposes․

Safety Precautions

Your Heatilator gas fireplace is designed with safety in mind, but adherence to these precautions is crucial․ Always ensure proper ventilation and never obstruct airflow to the fireplace․ Keep combustible materials a safe distance away from the unit, as specified in the installation manual․

Regularly inspect the fireplace for any damage or unusual conditions․ Never attempt repairs yourself; contact a qualified technician․ Be aware of the risks of carbon monoxide poisoning and install carbon monoxide detectors․ Prioritize safety to enjoy your fireplace responsibly․

Carbon Monoxide Warnings

Carbon monoxide (CO) is a colorless, odorless, and poisonous gas․ A malfunctioning gas fireplace can produce CO, posing a serious health risk․ Install CO detectors near the fireplace and on every level of your home, testing them regularly․

Recognize the symptoms of CO poisoning: headache, dizziness, nausea, and confusion․ If a detector alarms, immediately evacuate and call emergency services․ Never ignore a CO alarm! Proper installation, ventilation, and regular maintenance are vital to prevent CO buildup and ensure safe operation․

General Safety Guidelines

Always operate your Heatilator fireplace according to these guidelines․ Keep combustible materials, like furniture and curtains, a safe distance from the fireplace․ Never leave children unattended near the operating unit․ Ensure proper ventilation is maintained during operation․

Do not use the fireplace as a drying rack for clothing or other items․ Regularly inspect the glass door for cracks or damage․ If you smell gas, shut off the gas supply and contact a qualified technician immediately․ Prioritize safety to enjoy your fireplace responsibly․

Installation Requirements

Professional installation is highly recommended to ensure safe and efficient operation of your Heatilator gas fireplace․ Proper gas supply connection is crucial, adhering to local codes and regulations․ The ventilation system must be compatible with the fireplace model, ensuring adequate airflow for combustion and exhaust․

Verify sufficient clearances from combustible materials, as specified in the manual․ Incorrect installation can lead to hazardous conditions, including carbon monoxide poisoning․ Always consult a qualified technician for any installation concerns or modifications․

Gas Supply Connection

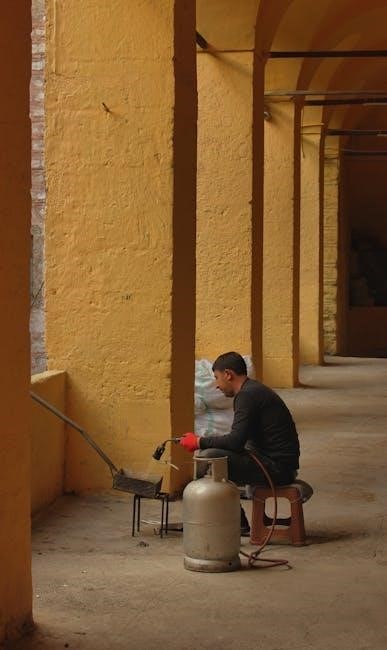

A qualified gas technician must perform the gas supply connection, ensuring compliance with local codes and manufacturer’s instructions․ The gas supply line should be sized appropriately for the fireplace’s BTU input․ Always use a properly sized and approved gas pipe, and apply pipe joint compound suitable for gas lines․

Before connecting, perform a leak test using a soap solution․ Never use an open flame to check for leaks․ Shut off the gas supply before making any connections or adjustments․ Improper connection can result in dangerous gas leaks․

Ventilation System Compatibility

Heatilator gas fireplaces require a properly installed and compatible venting system to ensure safe and efficient operation․ Always adhere to the venting guidelines specified in this manual and local building codes․ Using incorrect venting can lead to carbon monoxide buildup and pose a serious safety hazard․

Verify the vent type (direct vent or natural vent) matches your fireplace model․ Inspect the vent pipe for any obstructions or damage before each heating season․ Proper venting is crucial for removing combustion gases safely from your home․

Operating Instructions

Before initial use, carefully review all safety precautions outlined in this manual․ Ensure the area around the fireplace is clear of combustible materials․ For the Initial Startup Procedure, follow the detailed steps provided, typically involving turning the gas supply on and initiating the ignition sequence․

Ignition and Flame Control are usually managed via a control valve or remote․ Adjust the flame height to your desired comfort level, observing the flame pattern for consistent and complete combustion․ Never operate the fireplace with the glass front removed․

Initial Startup Procedure

Prior to the first use, a thorough inspection is crucial․ Confirm the gas supply is fully connected and the shut-off valve is open․ Slowly turn the fireplace control knob to the “Pilot” position, following the specific instructions for your model․ Press and hold the pilot button to ignite the pilot flame; continue holding for the recommended duration (typically 30-60 seconds)․

Once the pilot is established, turn the control knob to “On” and observe the main burner ignition․ If the burner doesn’t light, repeat the pilot lighting process․ Always check for gas leaks using a soapy water solution․

Ignition and Flame Control

Your Heatilator fireplace utilizes a reliable ignition system controlled via a knob or remote․ Turning the control knob clockwise typically increases flame height, while counterclockwise decreases it․ Some models feature modulating flames for precise heat adjustment․ Ensure the pilot light remains lit for consistent ignition; a weak or extinguished pilot will prevent burner activation․

If ignition fails, verify the gas supply and pilot light․ Remote controls offer convenient flame adjustment and on/off functionality․ Always supervise children and pets near the fireplace, and never leave it unattended while operating․

Remote Control Operation

Your Heatilator remote control provides convenient, wireless operation of your gas fireplace․ Typically, buttons control power (on/off), flame height adjustment, and potentially fan speed․ Ensure the remote has fresh batteries for optimal performance․ Pairing may be required initially; consult your specific model’s instructions for the pairing process;

The remote’s range is limited, so operate it within a reasonable distance of the fireplace․ Obstructions can interfere with the signal․ Some remotes feature programmable settings or timers for automated operation, enhancing comfort and energy efficiency․

Maintenance and Cleaning

Regular maintenance ensures your Heatilator fireplace operates safely and efficiently․ Periodically inspect the log set for damage or improper placement, cleaning it with a soft brush to remove dust and soot․ The pilot light requires occasional cleaning; follow the manufacturer’s instructions carefully to avoid gas leaks or malfunctions․

Always turn off the gas supply before performing any maintenance․ Inspect the glass door for cracks or damage, cleaning it with a fireplace-specific glass cleaner․ Annual professional inspection is recommended to verify proper operation and safety․

Log Set Inspection and Cleaning

Regularly inspect the log set for any signs of damage, such as cracks or crumbling․ Ensure logs are positioned correctly, following the original arrangement for optimal flame appearance and safe operation․ Clean the logs periodically using a soft brush or vacuum with a brush attachment to remove dust and soot accumulation․

Avoid using abrasive cleaners or chemicals, as these can damage the log material․ Handle the logs carefully to prevent breakage․ A clean log set contributes to a realistic flame pattern and efficient combustion․

Pilot Light Cleaning

A clean pilot light is crucial for reliable fireplace operation․ If the pilot light appears weak or irregular, carefully clean the pilot assembly․ Turn off the gas supply before attempting any cleaning․ Use a soft brush or compressed air to gently remove dust and debris from the pilot orifice and surrounding areas․

Avoid using wire or sharp objects that could enlarge or damage the orifice․ Ensure the pilot light flame is blue and steady after cleaning․ If problems persist, consult a qualified technician for assistance․ A properly maintained pilot light ensures safe and efficient ignition․

Troubleshooting Common Issues

Encountering issues with your Heatilator fireplace? This section addresses frequent problems․ No ignition often stems from a closed gas valve, a depleted battery in the remote, or a dirty pilot light – check these first․ A weak flame could indicate low gas pressure or a blocked vent․

Always prioritize safety; if you smell gas, immediately shut off the supply and contact a professional․ Refer to the detailed troubleshooting guides within this manual for specific model assistance․ Never attempt repairs beyond your expertise․

No Ignition

If your Heatilator fireplace fails to ignite, begin by verifying the gas supply valve is fully open․ Check the remote control batteries; low batteries can prevent proper signal transmission․ A common cause is a dirty or extinguished pilot light – follow the “Pilot Light Cleaning” instructions carefully․

Ensure the fireplace is receiving power․ If issues persist, consult a qualified technician․ Do not attempt to force ignition repeatedly, as this could lead to gas buildup․ Always prioritize safety and follow all warnings․

Weak Flame

A weak flame can indicate several issues․ First, verify the gas supply pressure is within the manufacturer’s specified range; low gas pressure is a frequent culprit․ Inspect the burner ports for obstructions – dust or debris can restrict gas flow․ Ensure the log set is properly positioned, as incorrect placement can disrupt flame patterns․

A partially clogged pilot light orifice may also contribute․ If the problem continues, contact a qualified technician for a thorough inspection of the gas valve and burner assembly․ Do not adjust gas supply components yourself․

Parts List and Diagrams

Detailed parts lists and exploded diagrams are crucial for maintenance and repair․ These resources identify each component of your Heatilator fireplace, facilitating accurate ordering of replacement parts․ Diagrams illustrate how parts assemble, aiding in correct reassembly after servicing․

Always reference your specific model number when ordering parts, as components vary between series (Crave, CD)․ Note that parts lists are procedurally generated and may require verification against the actual manual text before purchase․ Contact a qualified technician for assistance if needed․

Heatilator Crave Series Overview

The Crave series offers modern, linear gas fireplaces designed for contemporary living spaces․ Models include the Crave 36 Rev C 36, Crave Linear 6048 48, Crave60 Rev C 60, and Crave72 Rev C 72 – all Direct Vent (DV) configurations․ These fireplaces feature a mesmerizing ribbon flame and proven value․

The Rave adds a stylish element to any home or office․ Each model provides efficient heating and aesthetic appeal․ Refer to individual model specifications for detailed dimensions and venting requirements․ Always consult the specific manual for your Crave series fireplace․

Crave 36 Rev C 36 Gas Fireplace ー DV

The Crave 36 Rev C 36 is a Direct Vent gas fireplace offering a sleek, linear design․ This model is ideal for creating a modern focal point in your home․ It features a captivating ribbon flame and efficient heating capabilities․ Proper installation, adhering to local codes, is crucial for safe operation․

Consult the dedicated installation manual for detailed venting requirements and gas supply connection instructions․ Ensure compatibility with approved venting systems․ Regular maintenance, including log set inspection, will maximize performance and longevity․ Refer to the parts list for replacement components․

Crave Linear 6048 48 Gas Fireplace ー DV

The Crave Linear 6048 is a Direct Vent gas fireplace distinguished by its expansive 48-inch width and contemporary linear aesthetic․ It delivers a mesmerizing, long ribbon flame, enhancing any living space․ Installation must strictly follow local and national codes, prioritizing safety and efficiency․

Refer to the specific installation manual for detailed instructions regarding venting, gas connection, and clearances․ Verify compatibility with approved venting components․ Routine maintenance, including log set cleaning, is vital for optimal performance․ Consult the parts list for accurate component identification․

Crave60 Rev C 60 Gas Fireplace ー DV

The Crave60 Rev C is a Direct Vent gas fireplace offering a modern aesthetic with a 60-inch viewing area․ It features a captivating ribbon flame, creating a focal point in any room․ Proper installation is crucial, adhering to all local and national codes for safe and efficient operation․

Always consult the dedicated installation manual for precise instructions on venting, gas supply connection, and required clearances․ Ensure compatibility with approved venting systems․ Regular maintenance, including log set inspection, is essential․ Utilize the provided parts list for accurate component identification during servicing․

Crave72 Rev C 72 Gas Fireplace ⎻ DV

The Crave72 Rev C model delivers a stunning, linear fireplace experience with its expansive 72-inch viewing area․ As a Direct Vent unit, it prioritizes indoor air quality by exhausting combustion gases directly outside․ Installation must be performed by a qualified professional, strictly following the provided manual’s guidelines․

Pay close attention to venting requirements and gas supply connections to ensure safe and optimal performance․ Regularly inspect the log set and clean as needed to maintain the fireplace’s aesthetic appeal and functionality․ Refer to the parts list for accurate component identification during maintenance or repair․

Heatilator CD Series Information

The Heatilator CD Series, encompassing models like CD4842IR-D and CD4236IR-D, offers a blend of classic design and reliable performance․ These gas fireplaces are engineered for safety, efficiency, and lasting enjoyment․ Installation requires adherence to local codes and the detailed instructions within the accompanying manual․

Proper venting is crucial for safe operation, and the manual provides specific guidance on compatible ventilation systems․ Regular maintenance, including log set inspection and pilot light cleaning, will ensure optimal functionality․ Always consult the manual before attempting any repairs or part replacements․

CD4842IR-D & CD4842ILR-D Models

These CD Series models feature a 48-inch viewing area, providing a substantial and inviting focal point for any room․ The ‘IR’ and ‘ILR’ designations indicate different ignition systems and log arrangements, detailed within the installation manual․ Careful review of the manual is essential before installation and operation․

Ensure proper gas supply connection and ventilation system compatibility as outlined in the provided documentation․ Regularly inspect the log set for proper placement and cleanliness to maintain optimal flame appearance and performance․ Refer to the parts list for replacement components․

CD4236IR-D & CD4236ILR-D Models

The CD4236IR-D and CD4236ILR-D models offer a 42-inch viewing area, ideal for creating a cozy atmosphere in medium-sized spaces․ Like the 48-inch versions, the ‘IR’ and ‘ILR’ suffixes denote variations in ignition and log configurations – consult the installation manual for specifics․ Prioritize safety by adhering to all outlined precautions․

Proper ventilation is crucial for safe operation; verify compatibility with your existing system․ Maintain a clean log set and pilot light for efficient combustion and aesthetic appeal․ Refer to the included parts list when ordering replacements․

Mantel Specifications and Compatibility

Ensuring proper mantel clearance is vital for safety and preventing overheating․ Heatilator provides specific guidelines for mantel dimensions and materials, varying by fireplace model․ Atlas, Echo, and Luna models have defined compatibility parameters; however, these are not available for Caliber nXt Series․

Always consult the installation manual for detailed specifications․ Cast mantels are permitted as specified, but adherence to minimum clearances is non-negotiable․ Incorrect mantel installation can pose a fire hazard․ Verify compatibility before purchasing or installing any mantel․

Atlas, Echo, and Luna Models

Heatilator’s Atlas, Echo, and Luna mantel series offer distinct aesthetic options for enhancing your fireplace’s appearance․ These models are designed with specific clearances in mind, ensuring safe operation when installed correctly․ Detailed compatibility charts within the installation manual outline acceptable mantel projections and heights․

Proper installation is crucial; exceeding recommended dimensions can create a fire hazard․ These mantel series are not compatible with the Caliber nXt Series fireplaces․ Always prioritize safety and consult the manual for precise specifications related to your specific Heatilator model․

Warranty Information

Heatilator fireplaces are backed by a comprehensive warranty, protecting against defects in materials and workmanship․ The specific terms and duration of the warranty vary depending on the model and components․ Typically, the warranty covers the firebox, burner, and certain control systems for a specified period․

It’s essential to register your fireplace promptly after installation to activate the warranty․ Keep your proof of purchase and refer to the warranty document included with your fireplace for complete details, exclusions, and claim procedures․ Proper installation and maintenance are required to maintain warranty validity․

This comprehensive guide provides detailed instructions for the safe and effective operation of your Heatilator gas fireplace․ It covers essential aspects, from understanding your specific model and its features to proper installation, routine maintenance, and troubleshooting common issues․ Prioritize safety by carefully reviewing the warnings and precautions outlined within this manual․

Heatilator fireplaces are designed for utmost reliability and efficiency․ This manual ensures you maximize these benefits while enjoying the warmth and ambiance of your new fireplace․ Always refer to this guide before attempting any repairs or modifications․