Manhood is a journey requiring guidance‚ independence‚ and self-confidence. The Manual to Manhood offers a roadmap for young men‚ blending practical skills like cooking and self-reliance with personal growth.

Defining Manhood in the Modern World

Modern manhood emphasizes independence‚ self-confidence‚ and maturity. It involves mastering practical skills like cooking and self-reliance while fostering emotional intelligence and responsibility. The concept has evolved beyond traditional views‚ focusing on personal growth and resilience. The Manual to Manhood highlights these qualities‚ encouraging young men to embrace their potential and navigate life’s challenges with integrity and confidence.

Essential Life Skills Every Young Man Should Learn

Mastering practical skills like cooking‚ self-reliance‚ and problem-solving is crucial. These abilities foster independence‚ confidence‚ and readiness to handle life’s challenges effectively.

Cooking Basics: Preparing a Perfect Steak and Grilling

Cooking is a foundational life skill that fosters independence and confidence. Preparing a perfect steak involves seasoning‚ proper grilling techniques‚ and understanding cooking times. Grilling requires mastering heat control and timing to achieve the desired doneness. These skills not only enhance self-reliance but also provide a sense of accomplishment. The Manual to Manhood offers step-by-step guidance‚ ensuring young men can cook with confidence and impress others with their culinary abilities.

Household Skills: Changing a Tire and Finding a Stud in the Wall

Mastering household skills like changing a tire and finding a stud in the wall is crucial for independence. The Manual to Manhood provides clear instructions for these tasks‚ ensuring young men can handle emergencies confidently. Changing a tire involves gathering tools‚ loosening lug nuts‚ and safely replacing the flat. Finding a stud requires using a stud finder or knocking gently to locate wall supports. These skills foster self-reliance and preparedness for everyday challenges.

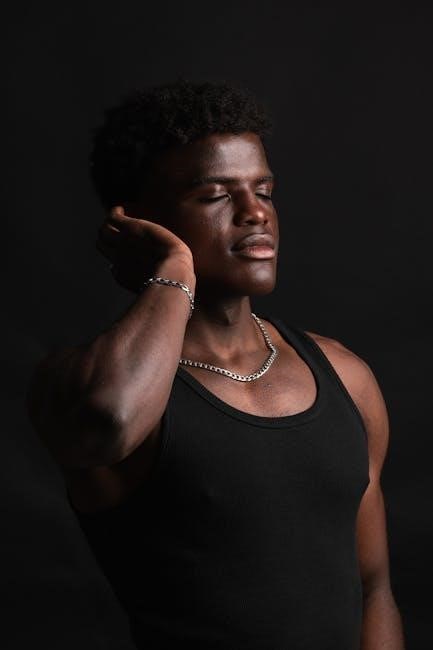

Personal Development and Self-Confidence

Personal development and self-confidence are foundational for manhood. The Manual to Manhood offers practical advice on building self-assurance‚ avoiding embarrassment‚ and maturing gracefully. It empowers young men to embrace their potential‚ fostering resilience and integrity in everyday life.

Building Self-Confidence and Avoiding Embarrassment

Building self-confidence is crucial for young men‚ as it shapes their ability to navigate life’s challenges. The Manual to Manhood provides practical advice on mastering essential skills‚ reducing embarrassment‚ and fostering maturity. By learning to cook‚ change a tire‚ and interact confidently‚ men gain the tools to avoid awkward situations. Sean Covey emphasizes that this guide helps young men build self-assurance and resilience‚ equipping them for real-world success and respect.

Practicing Maturity: Doing the Right Thing at the Right Time

Maturity is a practiced skill‚ demonstrated by making the right decisions at the right moment. The Manual to Manhood emphasizes mastering life skills like grilling a steak or tying a tie‚ which build confidence and avoid embarrassment. By learning these fundamentals‚ young men develop the wisdom to act appropriately‚ fostering respect and self-assurance. Mentorship and practical wisdom guide them in doing the right thing‚ every time.

Career and Financial Readiness

Career and financial readiness are essential for independence. The Manual to Manhood guides young men in creating resumes‚ preparing for interviews‚ and understanding financial literacy to build a secure future.

Creating a Resume and Preparing for Job Interviews

Creating a resume and preparing for job interviews are crucial steps in career readiness. The Manual to Manhood provides practical guidance on crafting a standout resume and mastering interview techniques. It emphasizes the importance of highlighting skills‚ experiences‚ and personal strengths to make a lasting impression. These skills not only enhance career prospects but also build confidence‚ essential for young men entering the professional world.

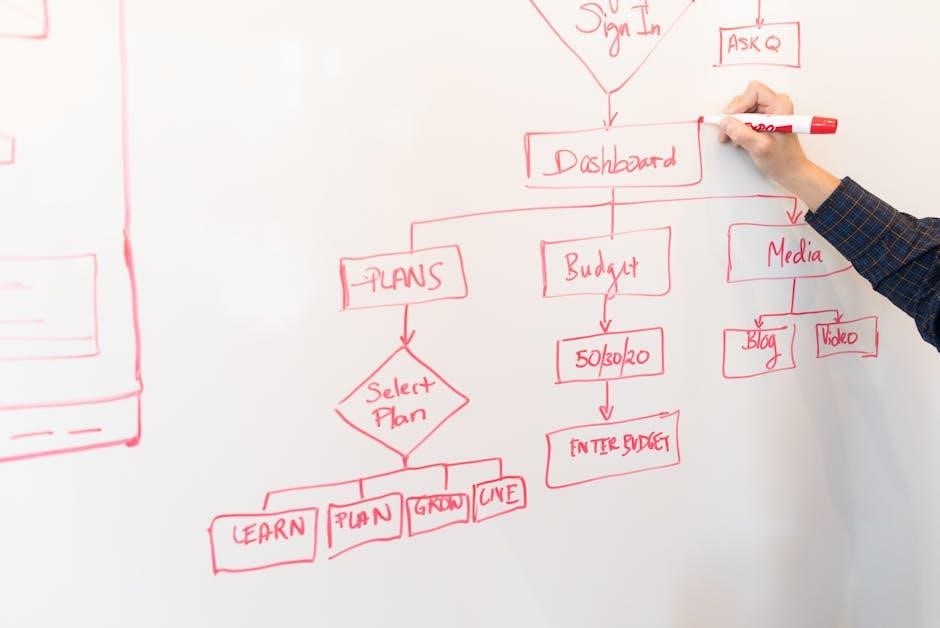

Understanding Financial Literacy for Independence

Financial literacy is a cornerstone of independence‚ teaching young men to manage money wisely. The Manual to Manhood emphasizes budgeting‚ saving‚ and investing to secure a stable future. By mastering these skills‚ individuals can avoid debt and make informed decisions‚ fostering financial freedom and confidence. This foundation is essential for achieving long-term goals and living independently‚ a key aspect of modern manhood. Sean Covey endorses this practical approach to building a secure financial future.

Relationships and Communication

Building meaningful relationships and mastering communication are vital for young men. The Manual to Manhood offers practical advice on how to impress a girl and effectively communicate‚ endorsed by Sean Covey for fostering confidence and independence.

How to Impress a Girl and Build Meaningful Relationships

The Manual to Manhood provides insights into building meaningful connections. It emphasizes confidence‚ respect‚ and genuine communication. Key advice includes understanding a girl’s perspective‚ being attentive‚ and fostering trust. Practical tips on conversation starters and body language are included‚ helping young men create lasting impressions and develop authentic relationships. These skills are essential for forming healthy‚ respectful partnerships.

Effective Communication Skills for All Situations

The Manual to Manhood highlights effective communication as a cornerstone of successful relationships. It teaches active listening‚ clarity‚ and empathy‚ emphasizing confidence and respect. Practical advice includes mastering conversations‚ understanding body language‚ and adapting communication styles to different situations. These skills foster trust‚ respect‚ and meaningful connections‚ essential for personal and professional interactions. By refining these abilities‚ young men can navigate all social scenarios with confidence and poise.

Health and Wellness for Men

The Manual to Manhood emphasizes the importance of physical and mental well-being. It provides practical advice on strengthening pelvic floor muscles and maintaining mental health through mentorship and resilience.

Physical Health: Strengthening Pelvic Floor Muscles

The Manual to Manhood highlights the importance of pelvic floor health for men. It outlines a structured 4-week Kegel exercise program‚ detailing exercises and sets to strengthen these muscles. Consistency is key‚ as stronger pelvic floors improve bladder control and overall physical well-being. This section emphasizes holistic health‚ linking physical strength to confidence and vitality‚ essential for a balanced journey to manhood.

Mental Health: The Importance of Mentorship

Mentorship plays a vital role in mental health‚ offering guidance and support during life’s challenges. The Manual to Manhood emphasizes the value of mentorship in building self-confidence and avoiding embarrassment. Sean Covey highlights how the book helps young men navigate common pitfalls‚ fostering resilience and emotional strength. Mentorship provides a foundation for mental well-being‚ encouraging men to embrace their full potential with clarity and purpose.

Social Etiquette and Respect

The Manual to Manhood emphasizes mastering social etiquette‚ such as tying a tie and dining manners‚ to earn respect and build confidence in all interactions.

Mastering Social Etiquette: Tying a Tie and Dining Manners

Mastering social etiquette is crucial for confidence and respect. The Manual to Manhood provides step-by-step guides on tying a tie and dining manners‚ ensuring young men navigate formal settings effortlessly. These skills not only enhance personal presentation but also demonstrate maturity and respect in professional and social environments‚ setting a foundation for lasting impressions and successful interactions. Proper etiquette fosters self-assurance and leaves a positive mark on others.

Understanding Respect in Relationships and Society

Respect is the cornerstone of healthy relationships and societal harmony. The Manual to Manhood emphasizes treating others with dignity‚ fostering meaningful connections‚ and contributing positively to communities. By understanding and practicing respect‚ young men build trust‚ earn admiration‚ and create a lasting impact in both personal and public spheres‚ embodying the values of true manhood and leadership in today’s world.

The Role of Mentorship in Manhood

Mentorship is vital for guiding young men through life’s challenges. The Manual to Manhood highlights how mentors offer wisdom‚ helping build confidence and respect. Mentorship fosters resilience and accountability‚ crucial for a man’s journey.

Why Mentorship is Crucial for Young Men

Mentorship provides young men with wisdom‚ fostering independence and confidence. It equips them with practical skills‚ emotional intelligence‚ and resilience. A mentor’s guidance helps navigate life’s challenges‚ avoiding common pitfalls. Through mentorship‚ young men learn to make responsible decisions and embrace their roles in society‚ building a strong foundation for successful manhood.

How to Find and Learn from a Mentor

Finding a mentor involves identifying role models who embody traits you admire. Be proactive by seeking guidance from experienced individuals in your community or profession. Approach mentors respectfully‚ showing genuine interest in their wisdom. Be teachable‚ open to feedback‚ and willing to apply their insights. A mentor’s knowledge can accelerate personal growth and equip you with the confidence to navigate life’s challenges effectively.

Overcoming Challenges and Avoiding Pitfalls

Overcoming challenges requires resilience and learning from mistakes. Embrace obstacles as growth opportunities‚ stay disciplined‚ and avoid common pitfalls to build a strong foundation for manhood.

Common Mistakes Young Men Make and How to Avoid Them

Young men often struggle with impulsiveness‚ lack of preparation‚ and poor time management. Common mistakes include neglecting mentorship‚ ignoring financial literacy‚ and avoiding difficult conversations. To avoid these pitfalls‚ focus on building self-discipline‚ seeking guidance‚ and embracing responsibility. Avoiding embarrassment starts with proactive learning and practicing maturity in decision-making. Resilience and accountability are key to overcoming these challenges and thriving on the journey to manhood.

Developing Resilience in the Face of Adversity

Resilience is a cornerstone of manhood‚ enabling young men to navigate life’s challenges with confidence. Adversity often reveals character‚ teaching valuable lessons in perseverance. By embracing a growth mindset and learning from mistakes‚ men can build mental toughness. Seeking mentorship and staying proactive in problem-solving fosters resilience. True strength lies in rising after setbacks‚ turning obstacles into opportunities for personal growth and maturity.

Manhood is a lifelong journey of growth‚ resilience‚ and purpose. Embrace challenges‚ learn from mistakes‚ and strive to become the best version of yourself.

Summarizing the Key Takeaways

The Manual to Manhood equips young men with essential life skills‚ fostering independence and confidence. It covers practical tasks like cooking and car maintenance‚ alongside personal growth‚ relationships‚ and financial literacy. The guide emphasizes maturity‚ respect‚ and resilience‚ encouraging men to embrace challenges and continuous self-improvement. By mastering these skills‚ young men can navigate life’s complexities with purpose and integrity‚ becoming well-rounded individuals ready to thrive.

Encouragement for the Journey Ahead

Embrace the journey to manhood with confidence and determination. The Manual to Manhood provides a roadmap for growth‚ helping you master practical skills and build character. Remember‚ manhood is a journey of resilience‚ integrity‚ and continuous learning. Stay focused‚ seek mentors‚ and surround yourself with supportive communities. With persistence and purpose‚ you’ll navigate life’s challenges and become the best version of yourself. The path ahead is yours to shape with courage and determination.