Overview of the Hayward AquaRite 900

The Hayward AquaRite 900 is a next-generation saltwater chlorinator designed for residential pools, offering efficient chlorine production and automated pool sanitation. It supports pools up to 40,000 gallons, ensuring clean and safe water with minimal maintenance. The system is known for its energy efficiency and user-friendly interface, making it a popular choice for pool owners seeking reliable and advanced water purification solutions;

The Hayward AquaRite 900 Series is a cutting-edge saltwater chlorination system designed for residential pools. Part of Hayward’s Expert Line, it offers advanced features like automated chlorine generation, intuitive controls, and energy efficiency. Built to handle pools up to 40,000 gallons, this series ensures consistent water sanitation with minimal maintenance. Its user-friendly interface and robust design make it a reliable choice for pool owners seeking superior water quality and convenience.

1.2 Key Features and Benefits

The Hayward AquaRite 900 offers advanced saltwater chlorination, automatically converting salt into chlorine for consistent sanitation. It features a user-friendly interface, energy-efficient operation, and compatibility with pool sizes up to 40,000 gallons. The system includes a diagnostic display for easy monitoring and maintenance. Its durable design ensures long-lasting performance, while its automated functions simplify pool care, making it a convenient and reliable choice for maintaining clean, safe, and enjoyable pool water year-round.

Installation and Setup

Installation requires a qualified technician to ensure proper electrical and plumbing connections, adhering to safety guidelines and manufacturer instructions for optimal performance and longevity of the system.

2.1 Pre-Installation Requirements

Before installing the Hayward AquaRite 900, ensure the system is turned off and all power is disconnected. Check the salt level in the pool, ensuring it meets the recommended 2300ppm minimum. Inspect the electrolytic cell for damage or scaling and clean if necessary. Verify proper plumbing connections and electrical compatibility. Adhere to all safety guidelines, including using copper conductors and avoiding power during installation. Ensure the control panel is ready for setup and calibration.

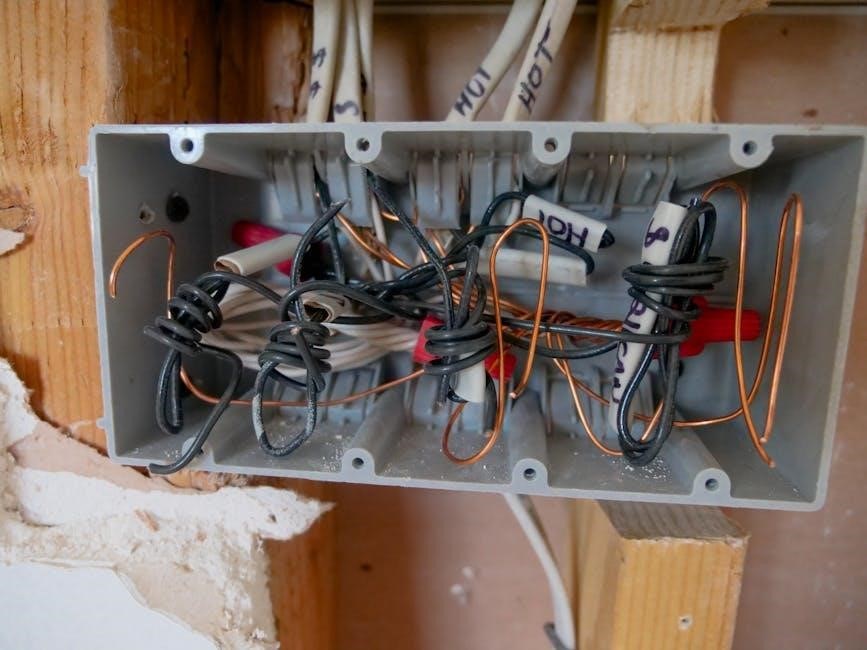

2.2 Step-by-Step Installation Guide

Mount the AquaRite 900 control panel near the pool equipment, ensuring easy access. Connect the electrolytic cell to the control unit, securing it with the provided hardware. Install the cell in the pool plumbing, ensuring proper flow direction. Wire the system according to the manual, connecting power and sensor cables. Prime the system by filling the cell with water. Turn on the power, set the desired chlorine output, and test the system for proper operation.

Operating Instructions

Power on the AquaRite 900, set the main switch to ‘Auto,’ and adjust the chlorine output dial as needed. Monitor salt levels and cell status regularly.

3.1 Initial Startup Process

Slide the main switch from ‘Off’ to ‘Auto’ to begin operation. Press the diagnostic button repeatedly until the desired settings are displayed. Ensure salt levels are above 2300 ppm for optimal performance. If salt levels are low, add salt and wait for the system to stabilize. Inspect the cell for cleanliness and rinse if necessary before starting. Allow the system to run continuously for 24-48 hours to establish proper chlorine levels.

3.2 Daily Operation and Monitoring

Daily monitoring involves checking the control panel for salt levels, chlorine production, and system status. Ensure salt levels remain above 2300 ppm for optimal performance. Regularly inspect the cell for cleanliness and rinse if debris is present. Monitor chlorine output and adjust the dial as needed to maintain desired levels. The system automatically adjusts production based on pool usage and water conditions, ensuring consistent sanitation and water quality.

Maintenance and Troubleshooting

Regular cell cleaning and salt level checks ensure optimal performance. Address issues like low salt alerts or flow problems promptly. Refer to the manual for diagnostic solutions and reset procedures to maintain efficiency and resolve common operational issues effectively.

4.1 Regular Maintenance Tasks

Regular maintenance ensures optimal performance of the Hayward AquaRite 900. Check salt levels weekly, clean the electrolytic cell every 3-6 months, and inspect the LED indicators for alerts. Reset the system after cleaning or addressing issues. Always refer to the manual for specific guidelines to maintain efficiency and prevent operational disruptions.

4.2 Common Issues and Solutions

Common issues with the Hayward AquaRite 900 include low salt levels, dirty cells, and error messages. Check salt levels and clean the cell every 3-6 months. If the “Inspect Cell” LED flashes, reset it by pressing the Diagnostic button for 3-5 seconds. For error codes, refer to the manual or contact Hayward support. Regular maintenance and proper troubleshooting ensure smooth operation and extend the system’s lifespan.

Safety Precautions

Always disconnect AC power during installation and use copper conductors only. Keep children away and handle chemicals with care. Store solutions safely and follow all instructions provided.

5.1 Important Safety Warnings

- Always disconnect AC power during installation and maintenance to avoid electrical shock.

- Use copper conductors only, as other materials may cause system malfunctions or safety hazards.

- Keep children away from the equipment and chemicals to prevent accidents.

- Handle chlorine generators and related chemicals with care, following all provided instructions.

- Store mixed solutions in a safe, well-ventilated area, out of harm’s way.

5.2 Handling Chemicals and Equipment

When handling chemicals and equipment for the Hayward AquaRite 900, always wear protective gloves and goggles. Store mixed solutions in a well-ventilated, secure area away from children. Follow the manufacturer’s instructions for proper disposal of chemicals. Avoid mixing different chemicals, and ensure all connections are secure before operation. Regularly inspect equipment for damage or wear to maintain safe and efficient performance.

Technical Specifications

The Hayward AquaRite 900 includes a control panel, electrolytic cell, and sensors. It operates with a maximum pressure of 2 bar and requires 2300 ppm salt for optimal performance.

6.1 System Components

The Hayward AquaRite 900 system includes a control panel, electrolytic cell, pH and temperature sensors, and wiring. The control panel manages automation, while the cell generates chlorine. Sensors monitor water conditions, ensuring optimal sanitation. The system also includes a power supply and communication interfaces for integration with pool equipment. Each component is designed for durability and seamless operation, supporting efficient pool maintenance.

6.2 Performance Metrics

The Hayward AquaRite 900 efficiently sanitizes pools up to 40,000 gallons, producing chlorine at a rate of 0.5 to 1;5 pounds per day; It operates at a low salt level of 3,000 ppm, reducing eye irritation and corrosion. The system features automatic pH control and real-time diagnostics, ensuring optimal performance.Its high-efficiency design minimizes energy consumption, making it both eco-friendly and cost-effective for pool owners seeking reliable water purification solutions.

User Reviews and Feedback

Users praise the Hayward AquaRite 900 for its ease of use, reliable performance, and effective water purification. Many highlight its energy efficiency and minimal maintenance requirements.

7.1 Customer Experiences

Customers have shared positive feedback about the Hayward AquaRite 900, highlighting its efficiency and ease of use. Many users appreciate its ability to maintain clean and safe pool water with minimal effort. Some mention initial setup can be complex, but overall, the system delivers reliable performance. A few users noted higher initial costs, but long-term savings on chlorine justify the investment. Most agree it enhances their pool experience significantly.

7.2 Overall Satisfaction

Pool owners express high satisfaction with the Hayward AquaRite 900, praising its efficiency and ease of maintenance. The system’s ability to consistently produce clean, safe water enhances overall pool enjoyment. While some users find the initial setup complex, the long-term benefits of reduced chlorine costs and automated operation outweigh these challenges. Overall, the AquaRite 900 is widely regarded as a reliable and valuable upgrade for pool sanitization systems.

Warranty and Support

The Hayward AquaRite 900 comes with a limited warranty covering parts and labor. Visit Hayward’s official website for detailed warranty terms and customer support options.

8;1 Warranty Information

The Hayward AquaRite 900 is backed by a limited warranty covering parts and labor for a specific period. Registration is required to activate the warranty. It typically covers defects in materials and workmanship under normal use. Conditions may apply, such as proper installation and maintenance. For detailed terms, refer to the official Hayward website or the product manual provided at purchase.

8.2 Contacting Hayward Support

For assistance with the Hayward AquaRite 900, visit the official Hayward website or contact their customer support team via phone, email, or live chat. Resources like manuals, troubleshooting guides, and FAQs are available online. Ensure to have your model number and serial number ready for efficient support. Hayward’s dedicated team provides help with installation, maintenance, and technical issues, ensuring optimal performance of your AquaRite 900 system.

Advanced Features

The Hayward AquaRite 900 offers advanced features like Salt Display, custom chlorine production, and integration with pool automation systems for seamless control and monitoring of water quality.

9.1 Customization Options

The Hayward AquaRite 900 offers advanced customization options, allowing users to adjust chlorine output, set salt levels, and program specific operation schedules. The system’s diagnostic button enables quick access to settings, while its intuitive interface simplifies adjustments. Customizable features ensure optimal performance tailored to individual pool needs, enhancing convenience and efficiency for pool owners.

9.2 Integration Capabilities

The Hayward AquaRite 900 seamlessly integrates with various pool systems, including remote controls and automation platforms. Its Ethernet connectivity enables advanced monitoring and control via compatible devices. The system is designed to work with Hayward’s OmniLogic and ProLogic automation systems, offering a unified pool management experience. This integration allows for synchronized operation of pumps, heaters, and lighting, enhancing efficiency and user convenience while maintaining optimal pool conditions.

The Hayward AquaRite 900 is a reliable and efficient saltwater chlorinator, offering advanced features for optimal pool sanitation. Its user-friendly design and integration capabilities make it a top choice for pool owners seeking a low-maintenance, high-performance solution.

10.1 Final Thoughts

The Hayward AquaRite 900 stands out as a high-efficiency saltwater chlorinator, delivering reliable pool sanitation with minimal upkeep. Its user-friendly interface and advanced integration capabilities ensure seamless operation, making it a preferred choice for pool owners seeking long-term performance and satisfaction.

10.2 Further Reading

For in-depth understanding and troubleshooting, refer to the official Hayward AquaRite 900 Series Owners Manual. Additional resources include Hayward’s website, which offers detailed guides, technical specifications, and user forums. These materials provide comprehensive insights into system operation, maintenance, and advanced customization options, ensuring optimal performance and longevity of your pool sanitation system.